The test systems of 4G-TeSys family make testing very easy, by quickly configuring test plans and executing tests, in support of validation process, and reporting test results.

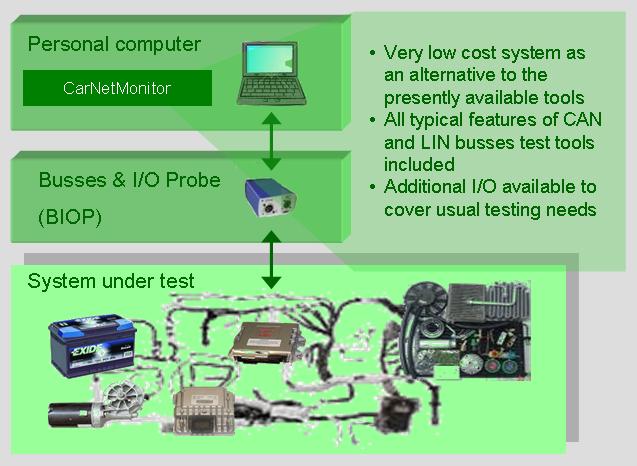

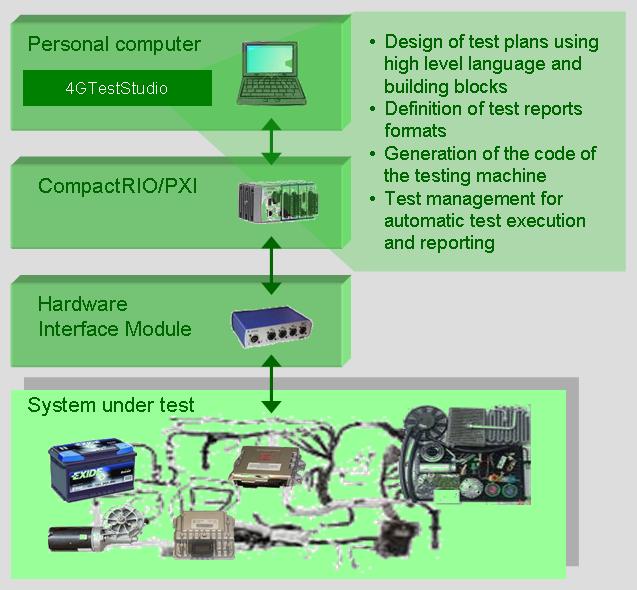

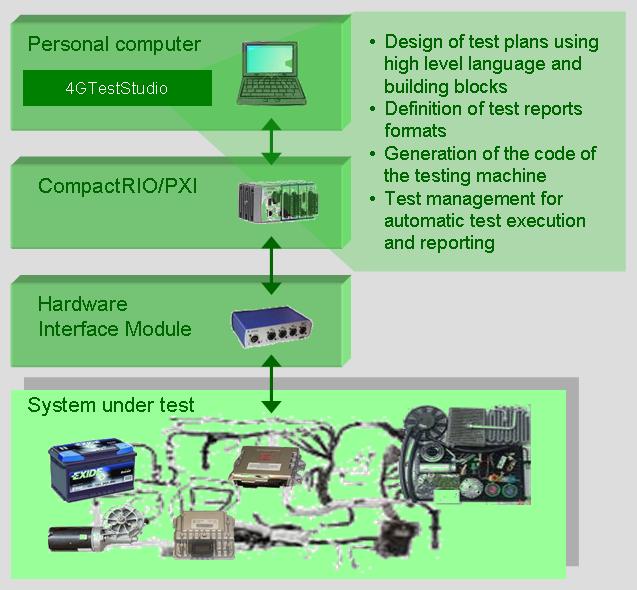

The systems are based on the reference 4G-TeSys configuration depicted hereafter.

4G-TeSys is constituted with the following elements:

- A Personal Computer, to program the test and process the results

- The 4GTestStudio suite, which contains the software tools to program the tests, define the results processing and the desired reports, and to generate the necessary codes to run the "testing machine"

- A "testing machine" to stimulate and to collect data, realized with National CompactRIO or PXI

- An Hardware Interface Module, which shall be custom designed, to adapt SUT (System Under Test) input/soutputs for signal conditioning and power driving.

CompactRIO™ and PXI™ are registered trademarks of National Instruments.

4G-TeSys configurations

Three different configurations enable fitting with almost all test requirements, both on-bench and on-vehicle (see the following table and the specific features of the systems).

| Test System |

Test type |

Test Operation |

Typical test application |

| 4G-TeSys-A |

Bench tests |

General purpose

Open loop operation

|

Vehicle systems |

| 4G-TeSys-B |

On-vehicle tests |

Soft real-time operation |

Body electronics |

| 4G-TeSys-B |

On-vehicle tests |

Hard real-time operation |

Vehicle dynamics, controllability tests, Functional Safety validation |

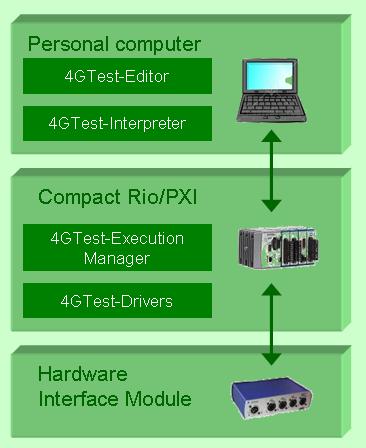

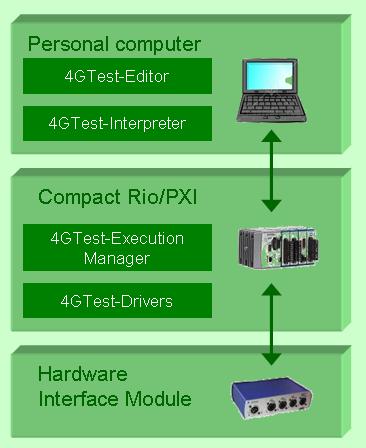

4G-TeSys-A

Features

- PC based operation for continuous test management

- Test execution and reporting via PC commands

- Test results analysis with post-processing

- Wide range of programming options

|

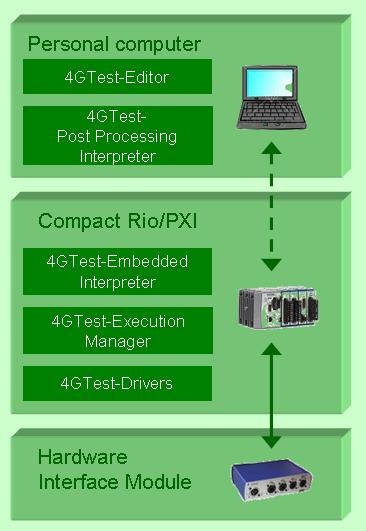

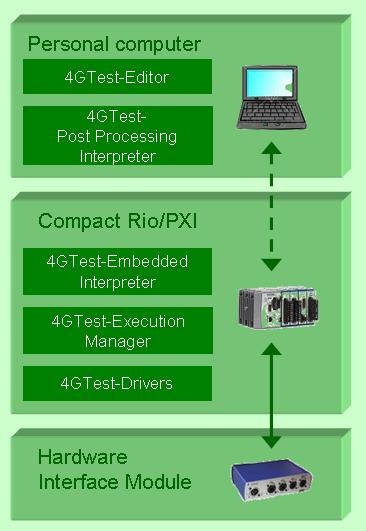

4G-TeSys-B

Features

- On-board, stand-alone operation capability

- Wide range of programming options

- Test sequences execution with embedded interpreter to replicate PC based programming

- On-board data recording

- Test results analysis with post-processing

|

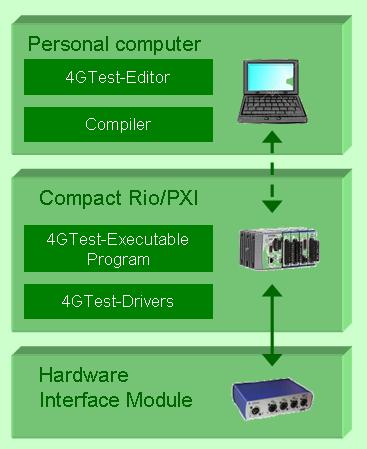

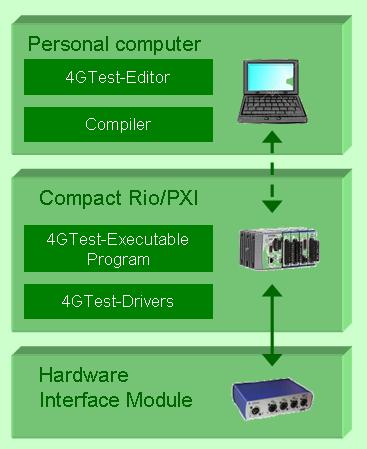

4G-TeSys-C

Features

- On-board, stand-alone operation capability

- Hard real-time operation capability

- Accurate measurements on condition and trigger events

- Test execution with executable code, downloaded from PC

- On-board data recording

- Test results analysis with post-processing

|

Interpreter availability: beta release: 2ndQ 2009, 1st release: 3rdQ 2009

How using 4G-TeSys

Each testing application requires the following activities: